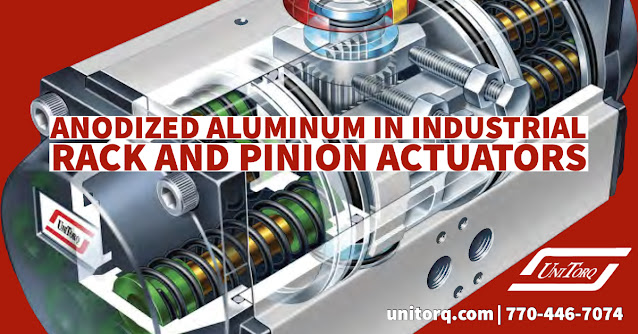

Rack and pinion actuators, widely used in industrial applications, deliver precise linear motion control. The preferred material for their construction is anodized aluminum due to its specific properties that enhance the performance and longevity of the actuators.

Anodized aluminum is lightweight, reducing the overall weight of the actuator system - a crucial factor in weight-sensitive industries like aerospace and automotive. Despite its lightweight, anodized aluminum retains considerable strength, making it suitable for applications demanding strength and durability.

The anodizing process converts the aluminum surface into a corrosion-resistant, anodic oxide finish, providing excellent protection from rust and other environmental corrosion. The thickness of this oxide layer depends on the type of anodizing—Type II or Type III—each providing different levels of corrosion resistance, surface hardness, and color vibrancy.

Type III, often called hard anodizing, forms a thicker oxide layer than Type II. This enhanced thickness results in superior wear resistance and durability, making it suitable for heavy-duty, high-wear applications. It also offers better resistance to high temperatures and produces a surface harder than tool steel. The downside of Type III is that it's less amenable to vibrant coloring due to its denser, less porous oxide layer and requires lower temperatures, higher current densities, and longer processing times.

In contrast, Type II anodizing, while producing a thinner oxide layer, is easier to color, making it more aesthetically adaptable. It's also a more cost-effective process, favoring applications where budget is a significant factor.

Anodized aluminum also offers high thermal conductivity, allowing effective heat dispersion, which is essential in applications where high heat could harm the actuator or shorten its lifespan. Furthermore, anodizing enhances the surface hardness of aluminum, which is beneficial for actuators operating in high wear-and-tear environments.

While anodized aluminum is a common choice, it's not universal, as the material selection depends on the application's specific requirements, environmental conditions, cost, and design constraints. Aesthetics also play, especially in consumer-facing applications, as anodized aluminum can be easily dyed to fit various color preferences.

The choice between Type II and Type III anodizing depends on the application requirements. Type III is the better choice for applications requiring maximum hardness and wear resistance, while Type II is preferable for cost-sensitive or aesthetically-focused applications.

https://unitorq.com

770-446-7074